About Us

Jiulong (Hebei) Fastener

Leveraging the industrial cluster advantages of Yongnian, known as the "Fastener Capital of China," our company is strategically located in Shahe City, Hebei Province, adjacent to Yongnian's core production area, ensuring convenient logistics and rich supply chain resources. Established in 2013, our factory covers a total area of 23000㎡, specializing in the R&D and manufacturing of high-strength fasteners and metal structural components.

Equipped with over 100 advanced machines, including cold heading machines and cold bending forming machines, we produce standard fasteners such as bolts, nuts, screws, washers, as well as new energy supporting products like solar mounting structures and wind power anchor bolts. Our in-house hot-dip galvanizing and heat treatment production lines enable full-process control from raw material processing to surface treatment, ensuring product performance meets international standards (ISO, ASTM, DIN, etc.).

Efficiency is at the core of our service: a 3,000-ton regular stock inventory, combined with a complete packaging and logistics system, ensure that the products are delivered to customers at the fastest speed. Our comprehensive quality inspection equipment and strict control processes—from raw material sampling to finished product mechanical testing—guarantee reliable quality for every item.

As a trusted fastener solution provider connecting global industries, we strive to be your long-term partner through large-scale production capacity, refined craftsmanship, and one-stop services.

Factory Figures

Area

Equipments

Stock

Real Factory Images

Office Building

Staff Canteen

All-staff group photo

Piece Cargo Warehouse

Loose Cargo Warehouse

Packaging Area

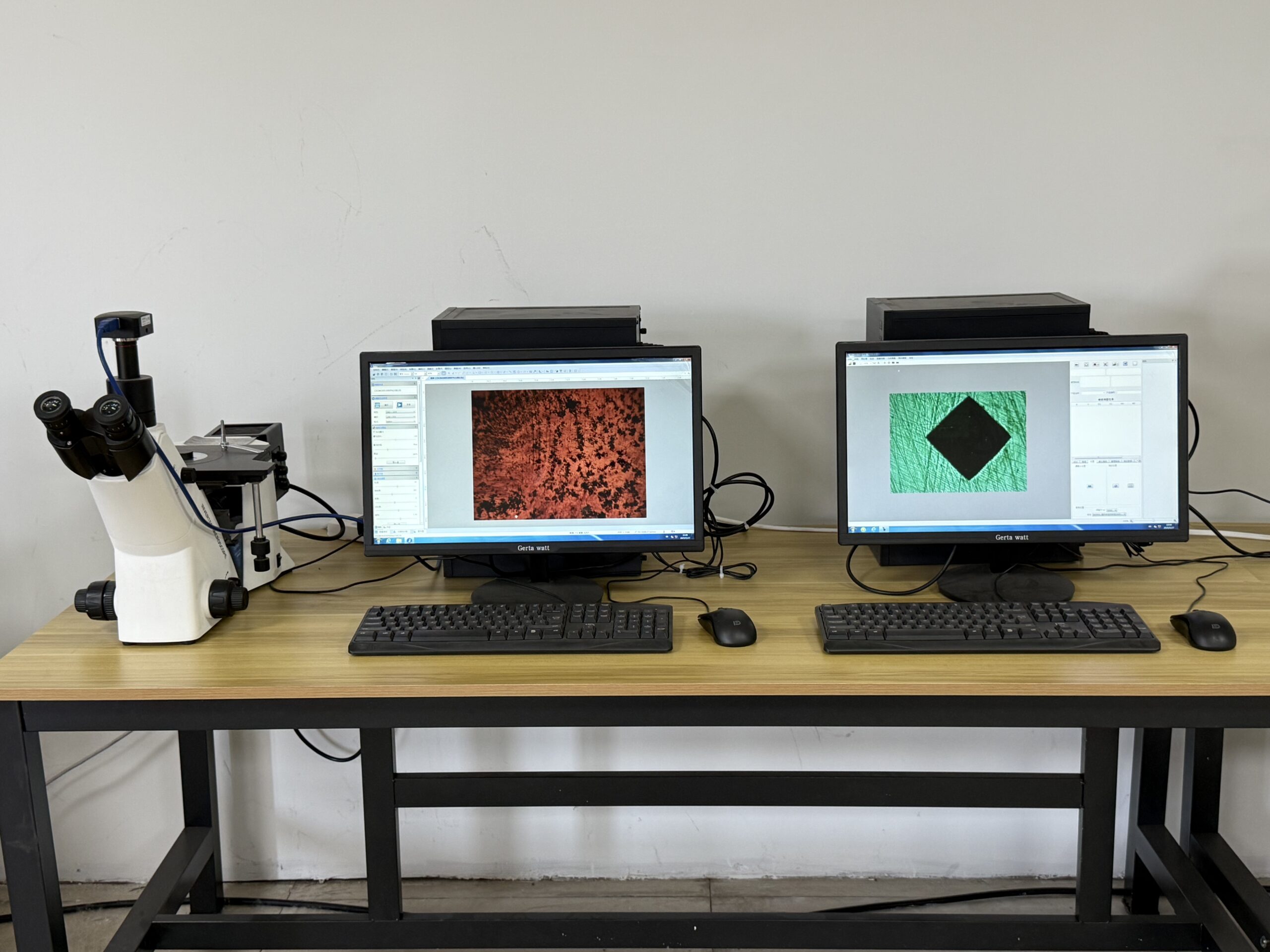

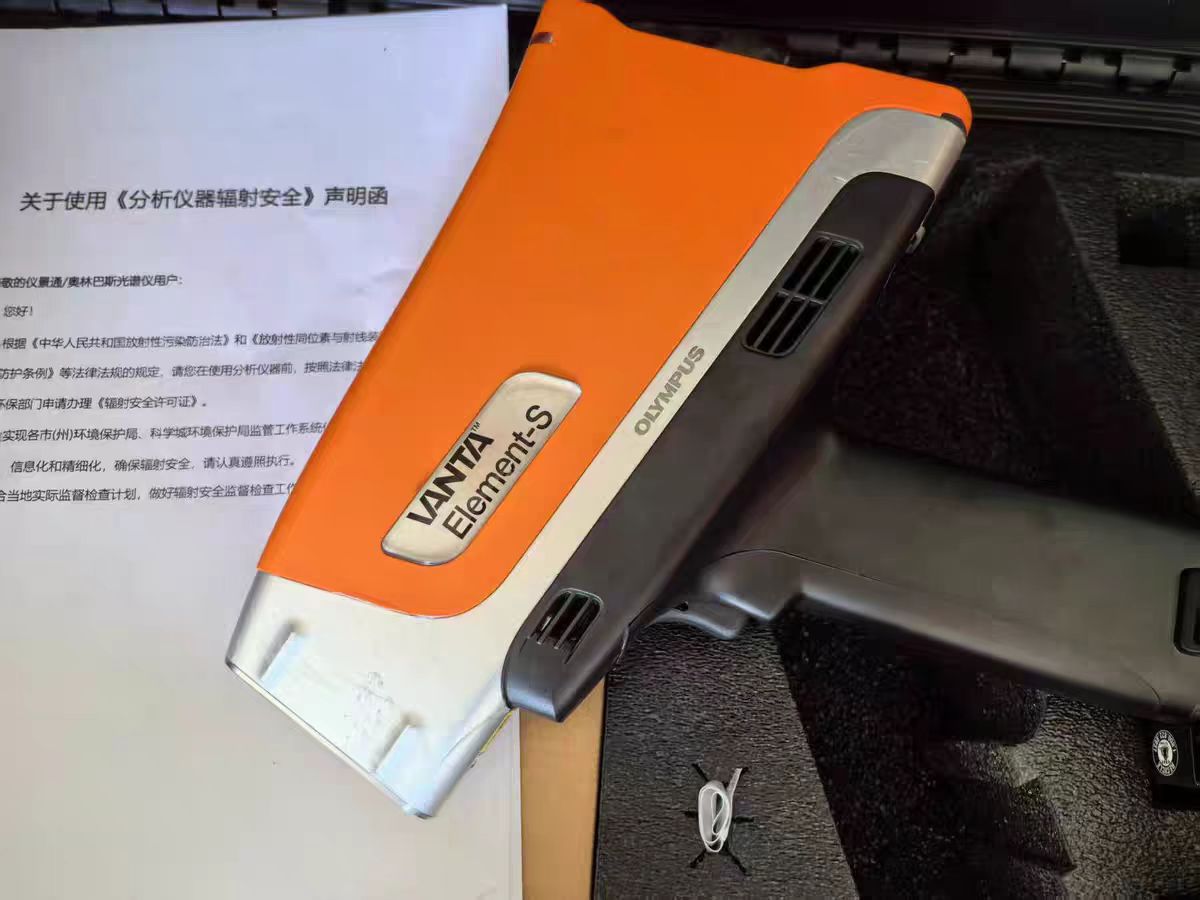

Detection Equipment Display

Magnetic Particle Testing

Impact Testing Machine

Universal Testing Machine

HV HR HB Hardness Tester

Metallographic Microscope

Handheld Spectrometer

Production Equipment Display

Bolt Thread Rolling Machine

Bolt Bending Machine

Screw Cold Heading Machine

Bolt Cold Heading Machine

Nut Tapping Machine

Strapping Machine